Overview

- The estimated turnaround time for this service is four to six weeks.

- Processing takes place at INO.

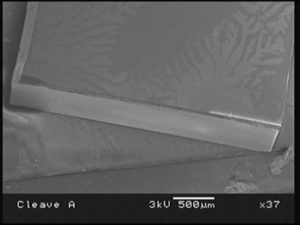

- Laser is used to trigger the location of cleaving.

- The cleaving is done with an accuracy of +/-15 µm.

- The technique provides good facet quality for end-fire coupling.

- Thin Silicon layers are accepted (up to 5 µm).

- For chip dimensions, see Guidelines for Laser Assisted Cleaving.

- We recommend alignment marks on chips to indicate where the cleaving is needed.

Applications

- Intended for use with Silicon photonics and other Silicon-based chips

- Cleaving along vertical plane of the waveguide

- Singulation of specific area of a chip