A University of Windsor research team and a small Canadian company are helping the automotive industry dramatically improve a key productivity factor, while creating skilled talent for the advanced technology manufacturing sector.

Windsor-based Laundau Gage, a producer of custom roundness gages used for inspecting automotive engine and transmission parts, was approached by one of its client manufacturers with a challenge: How to reduce the 20-minute-per-part inspection time needed for a widely used transmission line component?

Ensuring the accuracy, repeatability and quality of mechanical parts is crucial to competitiveness in the industry, says Ken Bishop, Vice-President of Operations at Landau Gage. “Getting the high level of detail needed to confirm those attributes more quickly leads to faster process adjustments and less production down time. This request immediately got me thinking about non-contact measurement.”

Realizing they didn’t have the expertise to address the problem on their own, Landau Gage turned to University of Windsor, where a novel application of electrical engineering knowledge, and support from the Natural Sciences and Engineering Council’s Engage program, provided the solution.

“Manufactured parts, especially transmission parts, have to be carefully measured,” explains Dr. Rashid Rashidzadeh, Manager of the Research Centre for Integrated Microsystems and Adjunct Professor at University of Windsor. “If a part is off by as little as 50 micrometres, it can cause transmission line failure.”

Current measurement systems use touch probes, making data-gathering and analysis time-consuming. Investigation by Rashidzadeh and his students showed that existing mechanical measuring systems weren’t the answer. Working with the company’s engineers for about a year, the research team developed a non-contact measuring system that uses lasers and algorithms to rapidly scan, capture and analyse thousands of data points on the round, grooved component.

“In the field of test and measurement, we know the techniques for mainly electrical circuits and systems, but had never applied these techniques to test and measurement of automotive parts,” says Rashidzadeh, whose research includes 3D integrated circuit testing, radio-frequency identification and smart sensors. “We used some of the techniques we knew and applied them to auto industry parts. That background in test and measurement helped us a lot.”

He credits that knowledge in part to past work with CMC Microsystems. “We gained this knowledge partially from information we received from CMC, and from solutions developed for testing chips fabricated through CMC.”

The results of the collaborators’ work were significant. When tested in a full parts run at the client manufacturer’s, their Non-Contact Measurement System reduced the company’s projected 34-hour inspection time to 90 minutes, or under two minutes per part – a 93 percent reduction in measuring time, says Rashidzadeh.

The patented system is now part of Landau Gage’s commercial product offerings, and an international company with 20,000 employees is already using the technology.

“This tool could have a huge impact on automotive supply companies, especially small companies,” says Bishop. “We hope to be able to export this all over the world.”

The project has produced more than a leading-edge product: It resulted in a full-time job at Landau Gage for one of Rashidzadeh’s students, as well as at least two internships. It also generated a waiting list of students eager to work in Rashidzadeh’s lab. “Students were volunteering to work on the project,” he says. “They like to go to industry and get involved. I came from industry, and I always advocate working with industry, because I know how valuable it is to apply knowledge in practice.”

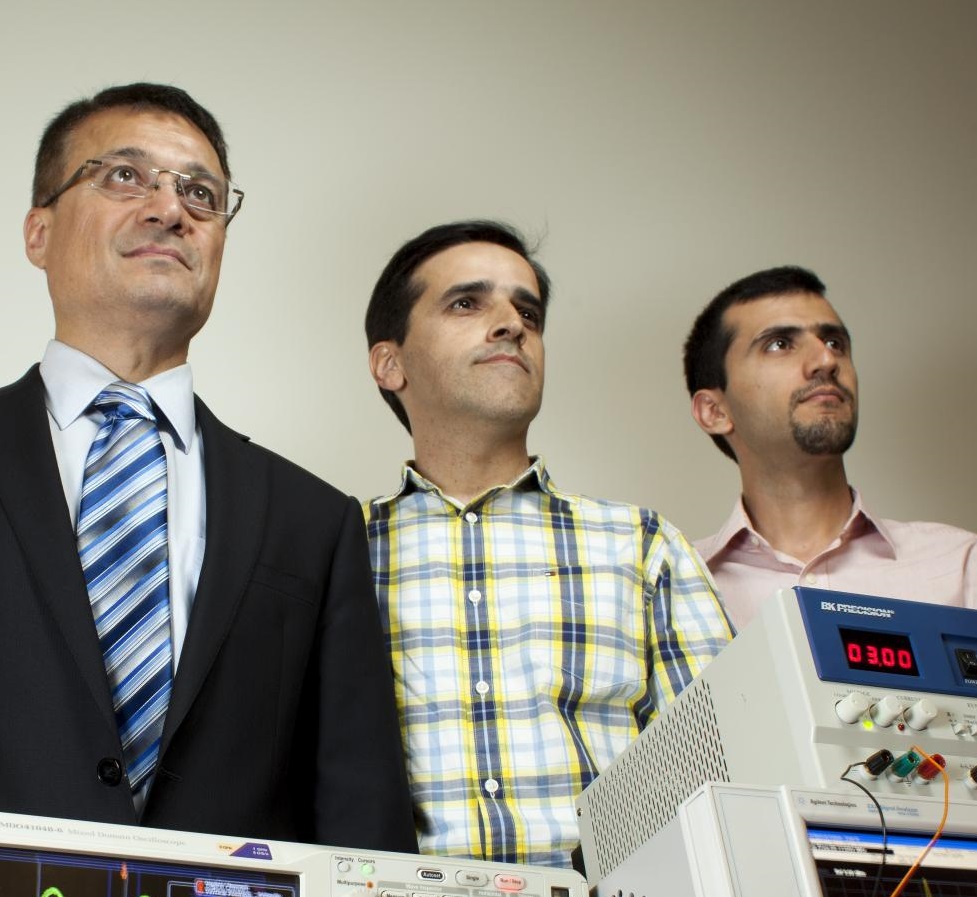

“The project couldn’t be completed without dedicated graduate students. I would like to recognize all of them for their contributions, and particularly acknowledge the role of Esrafil Jedari, Ali Mohammad Shanawaz and Mahmood Mirhashemi in the success of this project.”

Today Landau Gage continues to work with the University of Windsor group, who are developing a next-generation version of their laser system that incorporates mirrors with the laser, enabling illumination and measurement of small features deep inside components that can’t easily be reached. “It’s the first time this mirror-based solution has been used,” Rashidzadeh says. “There’s nothing else like it on the market. We’re excited about it.”

Photo Credit: Cosmin Nahaiciuc/Photo Features

August 2016