The advent of 3D printing promises to alter the way many commodities are manufactured, including intricate electronic components.

Today’s commercially available printers often employ simple polymer resins, which are fine for turning out equally simple items with few dynamic characteristics. Now Jun Yang, professor in Western University’s Department of Mechanical and Materials Engineering is pushing 3D printing in an exciting new direction.

Yang has spent much of his career working on surface chemistry, specifically how to modify and functionalize the properties of materials. Over the last few years he has been bringing this expertise to the field by developing a process called initiator-integrated 3D printing (i3DP).

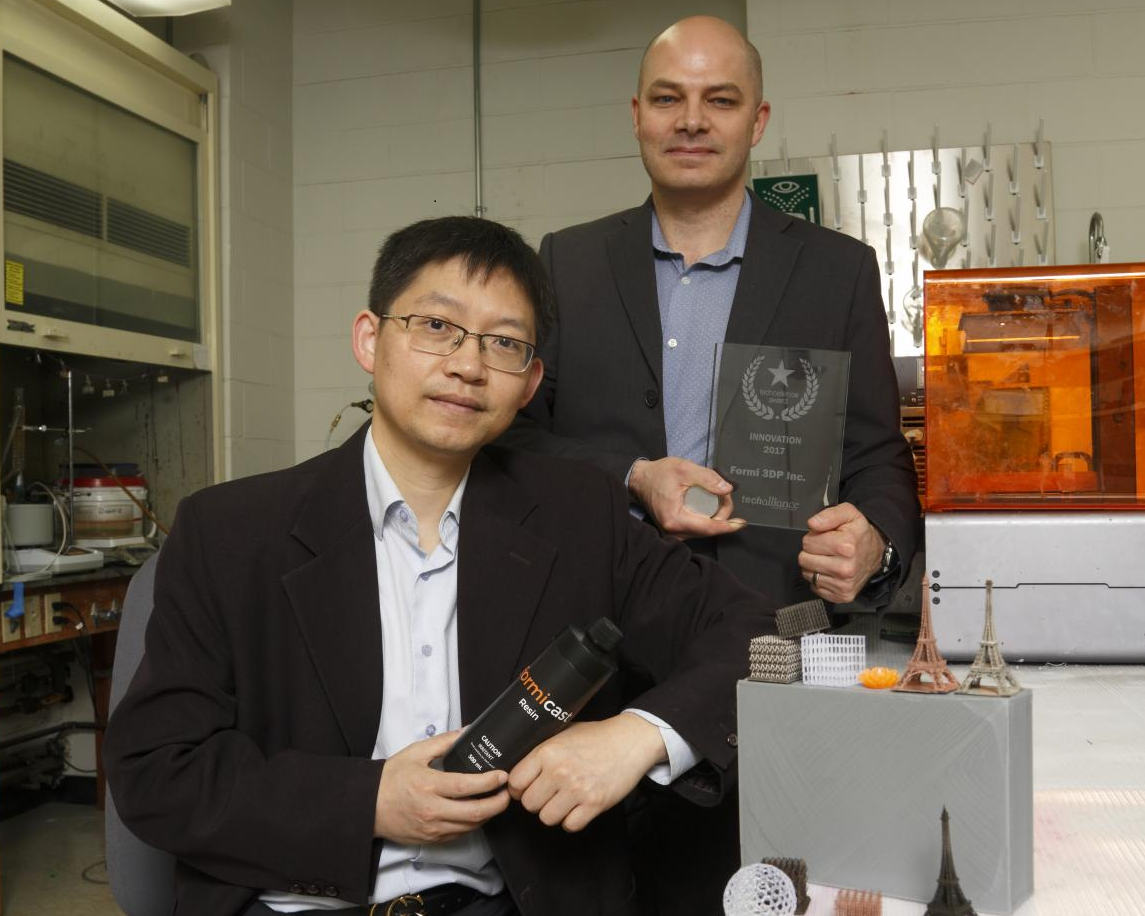

Today he is demonstrating the advantages of this approach through his startup company, Formi 3DP, which is commercializing and further refining the development resins and surface features that can be employed with 3D printing.

The starting point for i3DP is an initiator, a photopolymer that can be shaped with extreme precision, then used as a framework for casting other materials. For example, a piece of jewellery can be outlined, then subsequently finished through a process called electroless plating, which employs chemical reactions to create a seamless metal overlay on this intricate polymer structure.

Yang notes that there are 3D printers capable of turning out such jewellery directly with metal, but they can cost upward of $1 million. Using i3DP, this technique can be carried out on equipment worth just a few thousand dollars. In addition, the initiators employed in the original polymer compound can be adapted to define specific physical characteristics along the way.

“Until now, 3D printing has only been about structure,” he explains. “Now we’re saying you can also get function. For instance, we can make it hydrophobic or hydrophilic. We could also make it oil repellant, biocompatible, antimicrobial, even magnetic.”

The formal name for this method is surfaceinitiated, atomic-transfer radical polymerization (ATRP), but Yang prefers to describe it as the 3D printing equivalent of stem cells — a means of allowing materials to be adapted into a wide range of other materials, with an equally wide range of qualities.

Among the more compelling applications for ATRP is the efficient production of complex electronic circuitry.

“Currently it can cost several thousand dollars to prototype an antenna or wave guide,” says Yang. “But these same items can be 3D-printed for less than $100.”

He adds that 3D printing also brings the process of flexible electronics much closer to practical reality. Designers are currently struggling with the logistics of mounting completed circuitry on non-conventional substrates, such as textiles. ATRP would make it possible to embed the circuitry right in such a substrate, turning out the entire package in one step.

This particular initiative has led Yang to work closely with CMC Microsystems and he credits the organization with furthering his research.

“We have been able to make good use of equipment and software provided through CMC, which has been instrumental in our work,” he says. “Currently we are using CMC’s network analyzer to test the electronics we are producing.”

“We will be able to design finely detailed prototypes that people can use in advanced communication and manufacturing,” he says. “We have the ‘stem cells’ that can serve all of these purposes.”

The value of this work is already attracting attention: Earlier this year, his company received the TechAlliance 2017 Techcellence Award for Startup Innovation, in recognition of its industry-changing printing platform.

Photo: Steve Martin/Photo Features

May 2017