Ultrasound images of a fetus have become a rite of passage for parents-to-be, and while the emotional impact of such pictures is obvious, the sheer complexity of this imaging technology is easy to overlook. For his part, Tony Sinclair has immersed himself in the intricate details of ultrasonic sensing in a much broader suite of applications.

“My main use of ultrasound is for industrial applications — finding various types of material defects, figuring out how large they are, and whether they’re serious enough that we have to do something about them,” he says. “That sounds like a fairly narrow field but actually it’s got a lot of components in it.”

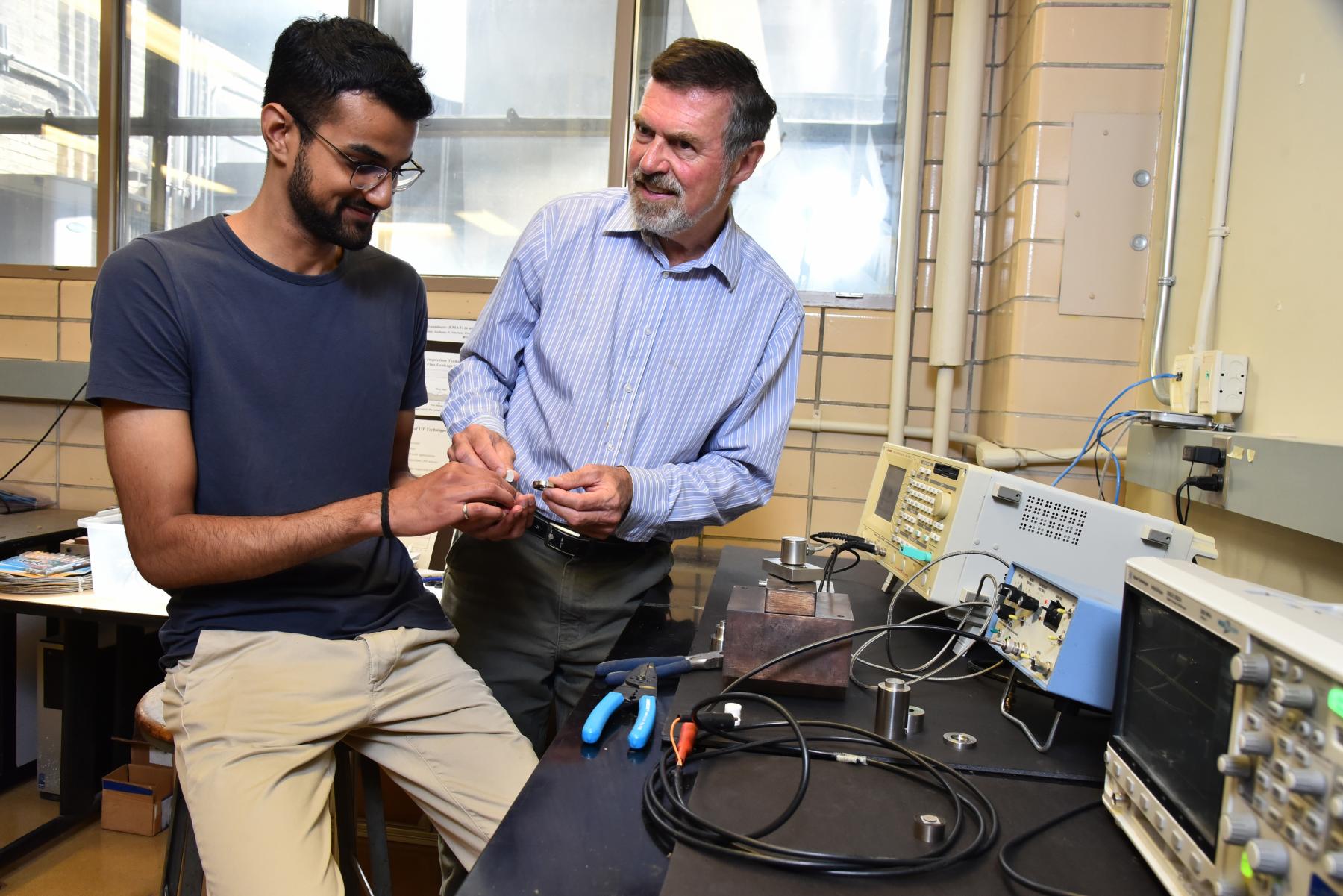

Sinclair, a professor of Mechanical and Industrial Engineering at the University of Toronto, considers both the hardware and software aspects of ultrasonic sensors. These are typically phased array systems, in which hundreds of tiny transducers send out signals in a carefully defined sequence, then receive information back from a target to create data points that together form a coherent image. These images are critical for revealing problems such as defective welds, or cracked materials – potentially disastrous conditions for infrastructure such as pipelines or nuclear plants.

“The hardware has already progressed to the point where it’s presenting a software challenge,” he explains. For example, each element in an array might generate 30 million data points each second; multiply that across a set of 256 elements and the number of data points increases by another two orders of magnitude.

“You’ve got to process these, store these, visualize them, turn them into a picture, display it for an operator who can then decide whether there’s a serious defect,” he says. “You’re dealing with horrendous amounts of data. You’ve got to develop very efficient ways of reducing the number of data points, and processing them in a way that gives a clear, accurate picture to the operator.”

Neither Sinclair nor his students are daunted by this prospect, as they work with business partners on ways of improving the collection and handling of information about the condition of infrastructure for industrial operations. One company that has been eager to collaborate is Advanced Measurement and Analysis Group (AMAG), an engineering firm in Mississauga, Ontario that specializes in advanced instrumentation for nuclear power plants.

The operators of these facilities would like to get real-time updates from transducers installed in less accessible parts of these plants, such as pipes carrying hot liquids. These hostile environments can reach several hundred degrees Celsius, which will melt the plastic components of typical piezoelectric sensors, and immobilize the elements at their core.

“AMAG has transducers that they’re buying commercially, but they’re many thousands of dollars each and they don’t last very long, so it’s been an expensive pain for them to go this route,” says Sinclair. “If they could get less expensive and more reliable transducers, they’d be able to convince companies to install more of them to monitor critical locations of their plants. It would also allow AMAG to move into other markets, such as monitoring high-temperature refinery processes.”

As part of their efforts to build more robust sensors, the University of Toronto team employs Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) tools from CMC Microsystems. Sinclair started making use of CMC’s offerings about five years ago and found it to be a valuable source of resources that might otherwise be exorbitantly expensive.

‘The hardware has already progressed to the point where it’s presenting a software challenge’

“They’re user-friendly,” he says. “The system doesn’t go down and I’ve found CMC to be very responsive. It’s worked well for me.”

He adds that such reliability has been essential to the demanding requests he and his colleagues regularly receive. These are usually brought forward by representatives from industry who are seeking a solution to a specific problem, such as trying to employ an ultrasonic transducer on a welded pipe made of stainless steel.

There is usually a way to address such problems, Sinclair says, although they can sometimes tax the expertise of researchers. “The engineers that design industrial systems are always thinking of new ways of giving us challenges. Nondestructive ultrasonic testing gives us the tools to create ever-more precise images to avoid disasters caused by defective materials.”

Photo: Rodney Daw/Photo Features

September 2018