Dr. Thomas Jones, founder, director, and CEO of Jones Microwave Inc., says that if the component works as well in the field as it does in the lab, it will allow cell phones and other devices to access higher bandwidths, speeding up downloads and enabling future applications such as extended reality.

High-frequency bands, such as millimeter-waves in the 30 to 300 GHz spectrum, are challenging to control. But as lower frequency, standard communication bands become more congested, millimeter-wave bands are expected to be essential for fifth-generation, or 5G technology, and Internet of Things (IoT) applications.

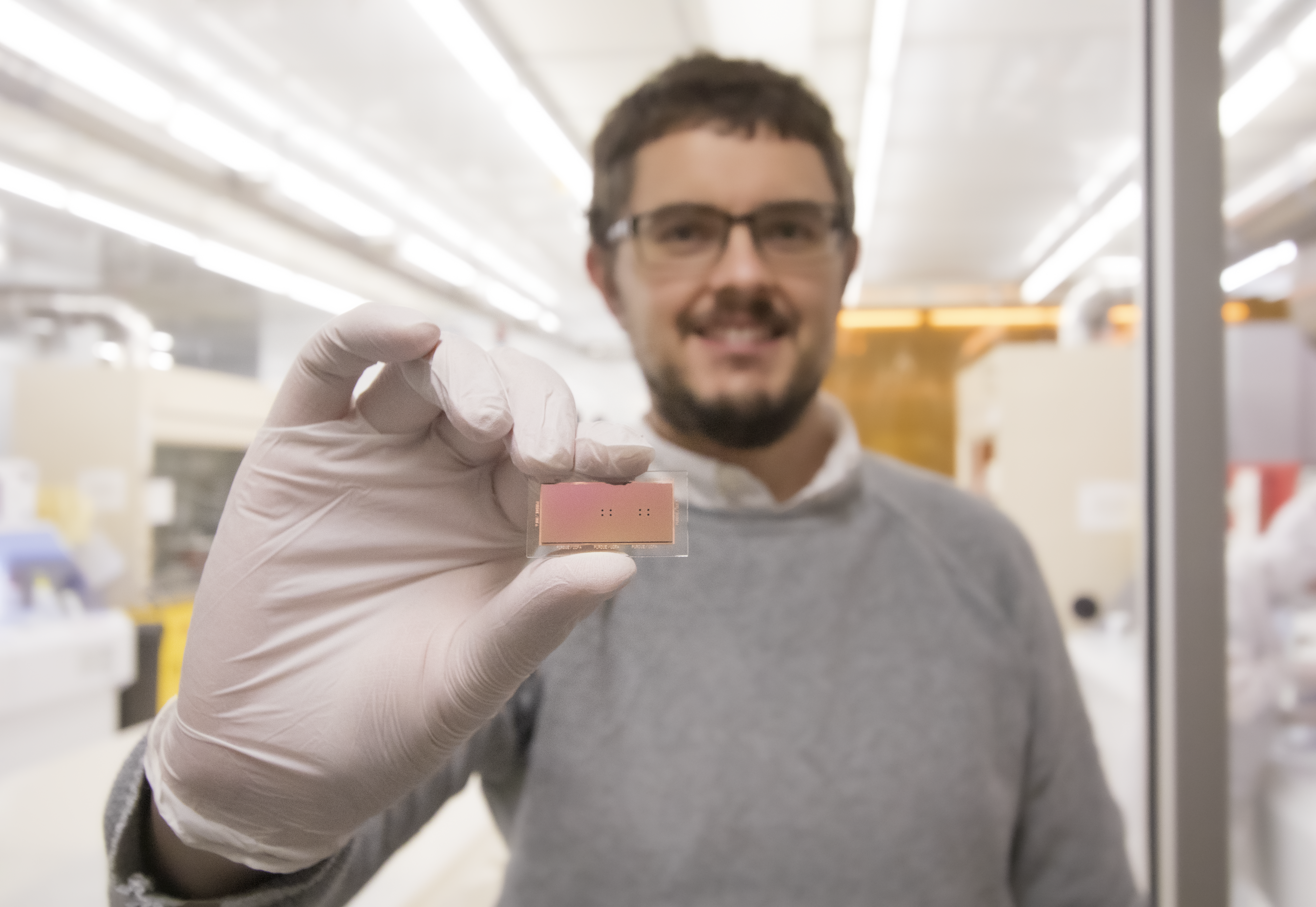

Jones says the switch can be integrated into waveguide systems or the back end of CMOS or other semiconductor processes. The fabrication lab nanoFAB located at the University of Alberta is producing the switch, which has been patented. The next step for Jones Microwave Inc. is to work with clients to build the component into their systems and field test it.

The company has a contract with the Department of National Defence. Jones says “In a war zone, you are in a battle for electromagnetic space: You must be able to adapt to the constant attempts to spy on and jam communication lines, so you need higher security communications. These higher frequencies enable the military to have a superior level of control over the flow of information.”

Jones began his research as a doctoral student working with Professor Mojgan Daneshmand, who led the Microwave to Millimetre-Wave (M2M) Lab at the University of Alberta and held the Canada Research Chair in Radio Frequency Microsystems for Communication and Sensing.

‘This has been a 10-year journey. CMC supported me throughout my PhD and post-doc and now as I build my own company.’

After he finished his doctorate, Jones traveled to Purdue University in Indiana to pursue a joint post-doctoral fellowship with Professor Dimitrios Peroulis and Professor Daneshmand. A few months later, in January 2020, Professor Daneshmand and her family tragically lost their lives in January 2020 when Ukrainian International Airlines Flight 752 was shot down in Tehran, Iran. Her death was a devastating loss, as they had worked closely together for seven years and were both friends and colleagues, but the legacy of her work and guidance continues. Jones says “She was very practical. We focused our research on technologies that are needed today. Her impact on my professional life and contributions to the global microwave community will never be forgotten.”

Jones says Professor Daneshmand was convinced high-frequency bands would be critical to the future of communications. After Professor Daneshmand’s death, U of A’s Professor Douglas Barlage took over her role, and with the continued support of Professor Peroulis from Purdue, helped Jones use silicon plasma technologies to address the challenges of controlling millimeter waves.

“Without the support and mentorship of both Professor Peroulis and Professor Barlage, I wouldn’t be starting the company I am today,” says Jones.

“As you go up in frequency, the wavelength gets smaller and smaller, so loss goes up and it gets harder to manufacture. Transistors are typically used as switches, and to operate at these speeds, they get smaller and smaller and can’t handle any kind of significant power,”

“Our technology can handle more power than transistor switches with substantially less loss.” The performance of the switch was so good, Jones decided to commercialize it. “We patented the technology and now I’m taking on an exciting investment from Brass Fund One LP that will help me take this company and technology to the market.”

Jones says CMC Microsystems provided invaluable help, including affordable licensing for CAD tools, providing industry-leading software for electronic design, access to a world-class clean room at the nanoFAB in Edmonton AB, and training in microfabrication. “This has been a 10-year journey. CMC supported me throughout my PhD and post-doc and now as I build my own company.”

Photo credit: Sanghamitro Das

March 2023