It’s not only kids who fear needles. Adults do as well, and many avoid medical treatment – including vaccinations – as a result.

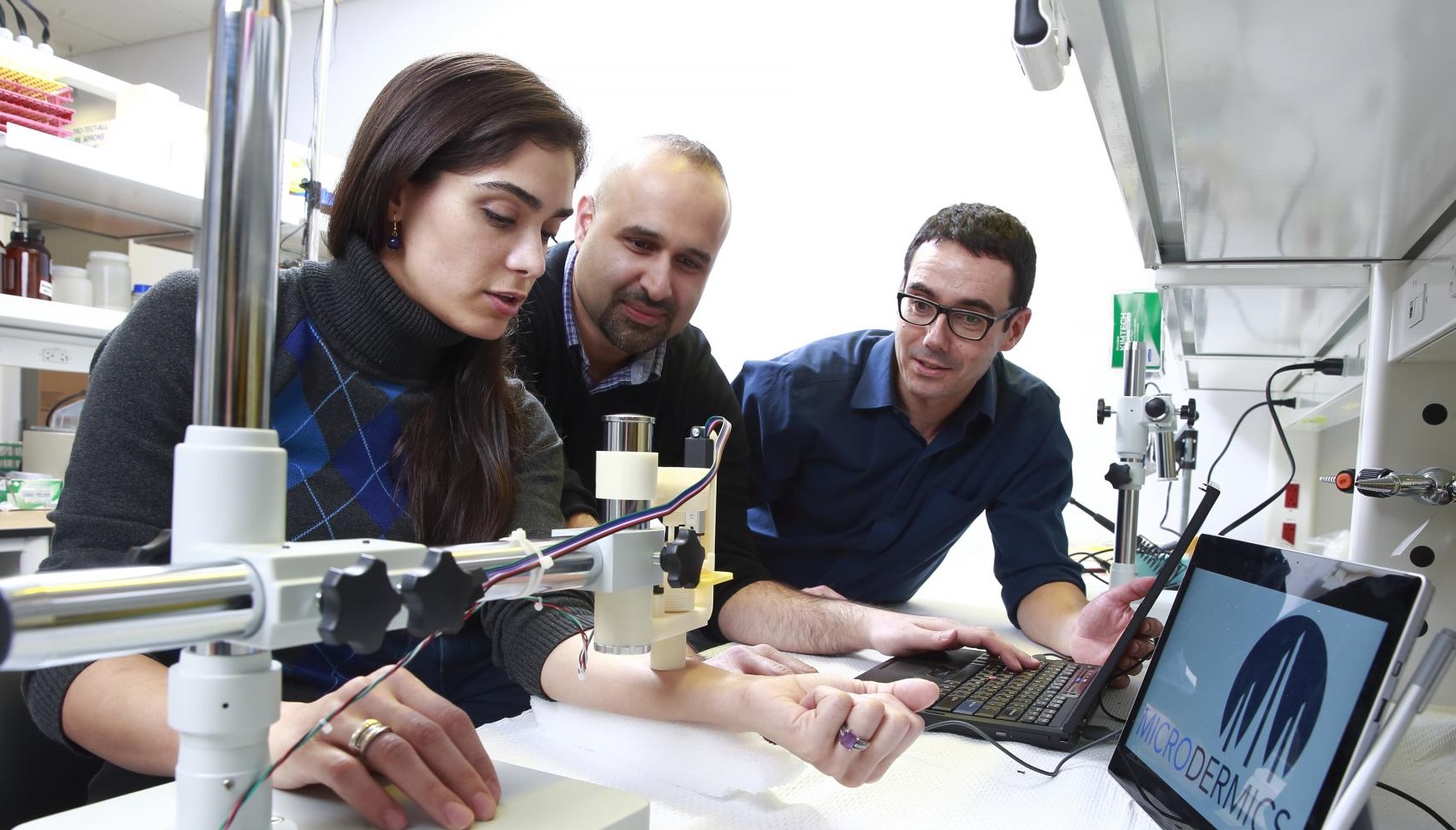

Vancouver-based startup Microdermics has a solution. It is developing a painless alternative to the hypodermic needle that could take the sting out of vaccinations, blood tests and other injections.

The company’s technology is a thin patch, smaller than a postage stamp, speckled with tiny, conical bumps. Each bump is a metal microneedle that delivers vaccines or drugs painlessly into the top layer of the skin, instead of into more pain-sensitive muscle.

This array of hollow metal microneedles barely penetrates the skin, so the injection feels like mild pressure rather than pain, says Boris Stoeber, a professor of mechanical engineering at the University of British Columbia and Canada Research Chair in Microfluidics and Sensing Technology. He co-founded Microdermics with Urs Häfeli, an associate professor in the Faculty of Pharmaceutical Sciences and an expert in nanomedicines and the science of drug delivery.

When they are used for vaccination, the microneedles have the benefit of requiring smaller doses of vaccine, he says, because skin – compared to muscle – is richer in immune cells that react after an inoculation.

While not the only company producing or developing these micro-needle arrays, Microdermics has some distinctive competitive advantages, Stoeber says. For one, its microneedles are metal, not silicon, which is brittle and can break easily.

Microdermics’ microneedles are also hollow, and can be used to inject vaccines in the same fashion as conventional needles. Other groups produce dissolvable needles, but they require a reformulation of existing drugs, something that requires regulatory approval.

A further distinction is that the company tailors the design of its arrays for optimal delivery of particular drugs by adjusting the length of its needles, which can vary from 350 to 850 microns (or a mere one-third to two-thirds of a millimetre) long. Human studies begin in 2017 to assess the effectiveness of this customized approach.

A significant advantage of the technology is its ease of use: the microneedles fit into a conventional syringe and don’t require any technical skill to administer. Stoeber foresees a day when consumers will be able to order vaccines online and inject themselves at home.

CMC Microsystems helped throughout the development process, he says, from CAD software for early design efforts to fabrication, which was made possible in part through CMC’s financial assistance awards, which cover up to 80 percent of micro-nano fabrication costs up to $2,000.

“The biggest challenges were in process and design,” he says. “Our technology allows us to make large quantities at low costs.”

More recently, Dr. Stoeber and his team have integrated an optofluidic biosensor into the microneedle array, creating a less invasive way to monitor the levels of therapeutic drugs in patients. Current monitoring uses hypodermic needles to extract blood several times a day; this alternative offers a faster, cheaper and painless process that might one day enable patients to self-monitor.

Barely piercing the skin, the microneedle technology collects a microscopically small amount (less than a millionth of a microliter) of interstitial fluid, the clear liquid found near the surface of the skin. Analytes inside the hollow needles react with the fluid, giving optical sensors the information they need to determine drug levels.

Earlier this fall CMC honoured Sahan Ranamukhaarachchi, Dr. Stoeber’s graduate student and company co-founder, with the Brian L. Barge Microsystems Integration Award for his work on the microneedleoptofluidic biosensor.

Microdermics also won the $110,000 first prize in the BC Innovation Council’s New Ventures BC annual competition, the largest start-up technology competition in the province.

“It is exciting to take something from the lab and bring it into the real world,” says Stoeber.

Photo Credit: Jeff Vinnick/Photo Features

January 2017