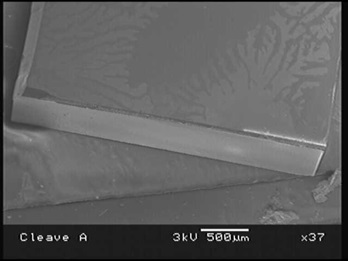

Generic AlN Carriers for Optoelectronic Applications

CMC has developed generic AlN carriers suitable for optoelectronic and microelectronic device testing. These carriers facilitate the testing and characterization of your chip, by providing: High-thermal conductivity RF compatible substrate for chip die bonding, wire bonding, and electrical/optical probing

Generic AlN Carriers for Optoelectronic Applications Read More »