In the emerging world of quantum technologies, researchers work at the unimaginably small scale of single atoms or particles, where the classical rules of physics don’t apply.

For John P. Davis, a nanomechanics specialist at University of Alberta, this exciting – and perplexing — new field posed an even more fundamental challenge: How do you investigate and develop innovations at the quantum scale when the instruments needed to measure those innovations don’t yet exist?

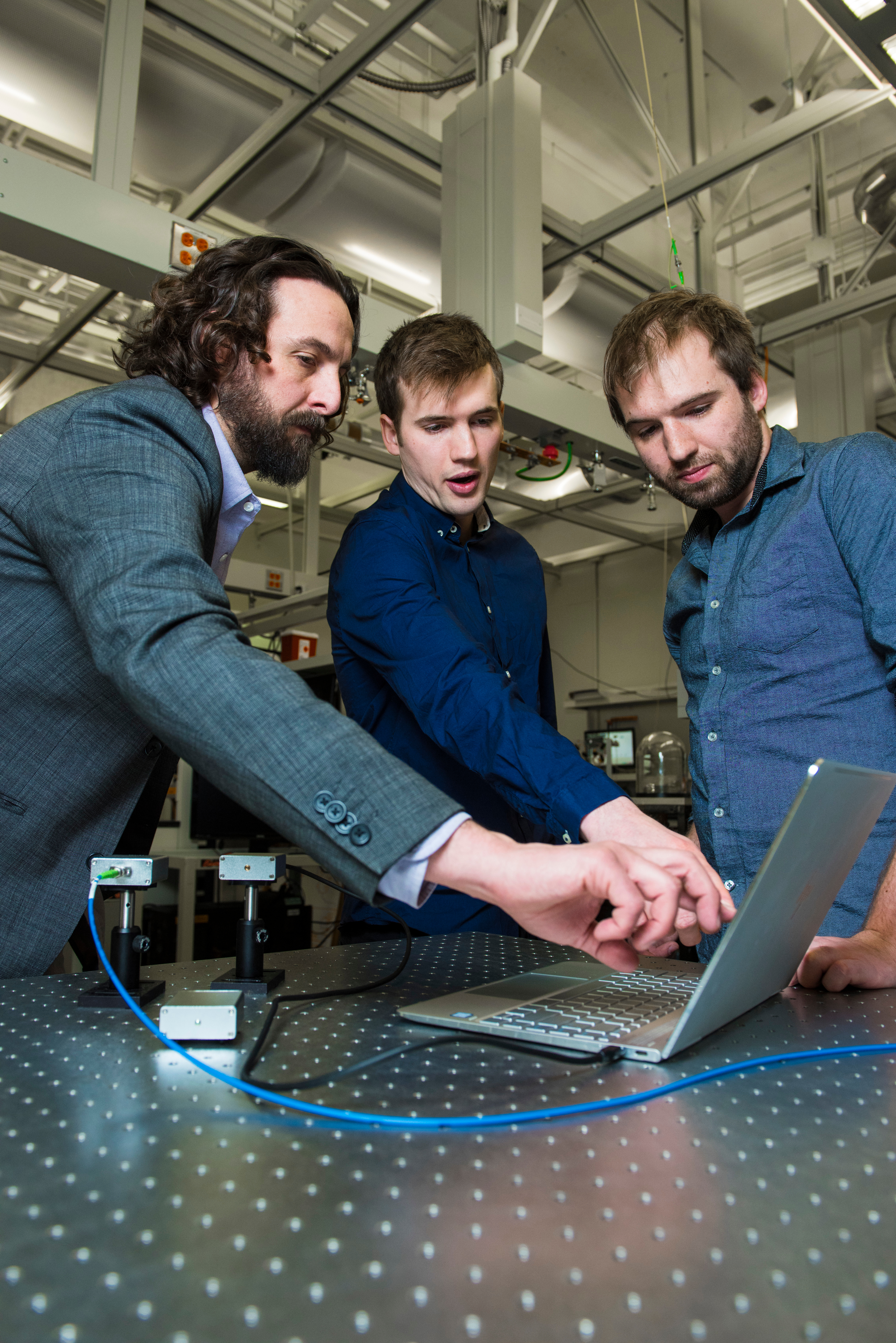

Now the Associate Professor of Physics and two of his students have started to fill this void. Earlier this year their startup company, Resolved Instruments (resolvedinstruments.com), began selling its first product, a digital photodetector that streamlines data-gathering and analysis of optical signals. These measurements are crucial in understanding the quantum behaviour of nano-scale mechanical systems.

One of Professor Davis’s research areas is looking at the quantum properties of tiny nanomechanical resonators – exquisitely small devices that measure mechanical displacement with extreme sensitivity. Capturing these measurements is possible using optomechanics, a technique in which the mechanical motion is captured and encoded in an optical signal.

“We’re working on trying to extract quantum behaviour from mechanical systems using this technique,” Davis explains. “The long-term goal is to make new quantum technologies, and to do that we need better detectors of optical signals.”

Davis and two of his students – brothers Pearse and Callum Doolin – met that challenge. “They had been working on the electronics to make better photodetectors and data acquisition systems, and they were so good at it, they thought maybe entrepreneurship was the way to go. So we formed a company.”

Their pioneering device, the first digital photodetector, streamlines the data-gathering process. “It takes that optical information and turns it into an digital signal that you can get into your computer,” Davis says. “Normally you would have needed an amplifier and a digitizer, and they’re very expensive. These guys packed all of this into a small device that has the lowest noise floor on the market. They simplified it and made it better.”

A good example of this technology’s applicability is in atomic force microscopy (AFM), used in nanotechnology R&D to capture and measure the features of nanomaterials. AFMs use a resonating cantilever that scans the surface, measuring its properties and forces. “One of the most precise ways to assess the motion of that cantilever is to bounce a laser off it,” Davis explains. “Light is encoding the information off that resonator. You need to get that information off that optical signal by shining it on a photodetector without adding a lot of noise, and then get the data into the computer.”

“Being able to sensitively measure the mechanics of nanoscale objects should enable us to build and fab devices that can, at extremely low temperatures, show quantum behaviour.”

The target market for their product is academic researchers, he says. “They want better measurements using real, modern digital technology. It could be practical research, such as doing photonics to build new telecommunications capabilities, or it could be biologists doing optical measurements.”

CMC Microsystems has helped Davis, his team, and their technology throughout the R&D process, he says. CMC helped them fabricate early designs through international silicon photonics foundries IMEC and LETI, until the need for faster iterations led them to the nanoFAB facility at the University of Alberta. Today they continue to benefit from design tools provided through CMC, particularly COMSOL, which allows them to simulate optical and mechanical systems. “We use COMSOL to design and understand the things we’re making in the nanoFAB.”

Their company has been swift to enter the market – incorporated in spring 2016, it began selling its first product in early 2017. “Our product continues to get better – I just saw a new version the other day,” Davis says. The company is developing new photodetectors and other pieces of digital electronics, with the aim of expanding its product portfolio in the coming year.

At the same time, they’ll be continuing to learn from their own ingenuity, says Davis. “The company is developing the instruments to help us measure the things we’re making.”

The capabilities provided by Resolved’s products are the way of the future, he predicts. “More and more graduate students are starting to see that the coming wave of technology is quantum-enabled, from computers to computation and cryptography. Training students for industry and entrepreneurship related to quantum is truly the next big thing.”

Photo: John Ulan, University of Alberta

August 2017