Toronto-based start up Micromensio has developed new technology to improve an old way of treating bacterial infections.

The company is pitching its low-cost, rapid sensing technology to companies working with bacteriophages—viruses that prey exclusively on bacteria.

Also called “nature’s own antibiotics,” bacteriophages were discovered in 1915, a decade before penicillin, and were used successfully to treat dysentery and cholera. But they were eclipsed by the development of broad-spectrum antibiotics that revolutionized medicine in the 20th century.

The threat of antibiotic resistance has led to renewed interest in how to use bacteriophages to safely treat infections. Phages are highly selective and target specific bacteria, but culturing bacteria taken from a patient sample to see if certain phages will work can take days.

That’s where Micromensio comes in. Unlike current diagnostic techniques, the company’s disposable, wireless microchips can be placed directly into a bacterial sample, and can tell within 15 minutes whether the phages successfully attacked the bacteria.

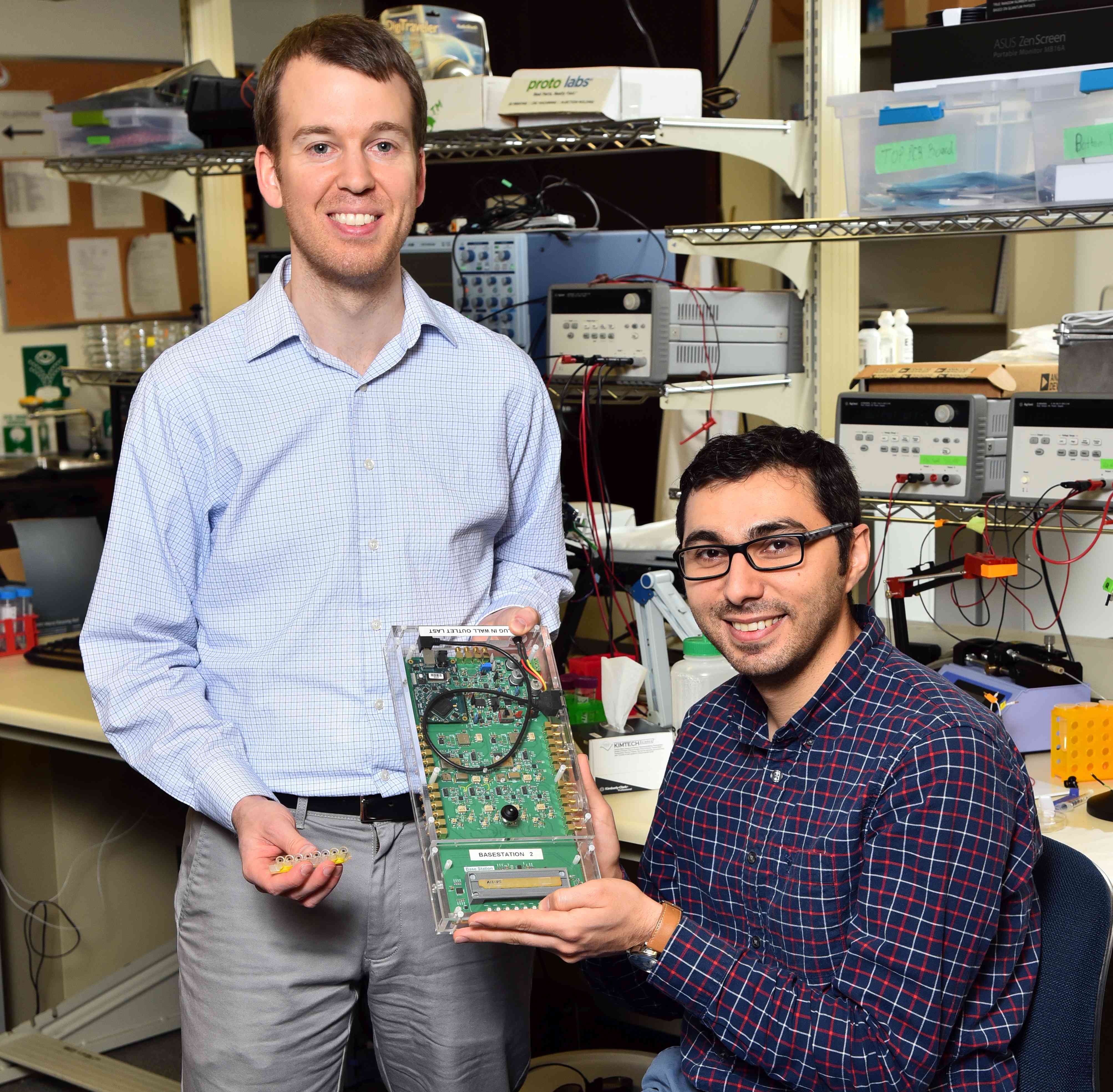

Micromensio founders Brendan Crowley and Enver Kilinc developed their prototype as post-doctoral fellows working with University of Toronto Professor Glenn Gulak who, with collaborators Karen Maxwell and Will Navarre, received a grant from the Canadian Institutes of Health Research (CIHR) and the Natural Sciences and Engineering Research Council (NSERC) to develop the technology and commercialize it. Their platform sensor system was designed from the start to be low-cost, mass-producible, and compatible with existing microbiology tools.

Crowley and Kilinc were inspired by the idea that they could help address the growing threat of antibiotic resistance. In January, the World Health Organization reported that some of the world’s most common—and potentially most dangerous—infections are proving resistant to drugs, including those that cause gastric disorders and pneumonia.

The team worked with Professor Maxwell’s microbiology lab at the University of Toronto to test its prototype microchips, which detect the potassium released when cell membranes of bacteria are breached by phages.

“If we see a quick increase in potassium levels, we know that the phage infected the bacteria,” says Crowley, “and by knowing which strains of bacteria a particular phage will infect, we can also identify the bacterial species.”

Sick Kids Hospital in Toronto provided bacterial samples for testing.

Phages have not yet been approved as a treatment for bacterial infections by the U.S Food and Drug Administration or by Health Canada. They have, however, been successfully used in Eastern Europe, where researchers continued to work on them after the Second World War because Eastern Bloc countries could not reliably import antibiotics from the West.

‘Crowley and Kilinc were inspired by the idea that they could help address the growing threat of antibiotic resistance’.

Earlier this year Micromensio won $35,000 in the recent Velocity Fund Finals pitch competition at the University of Waterloo, and has since joined the Velocity incubator program. It is currently seeking bacteriophage companies to test the product and is also looking for investors to help it scale up the technology.

The company has letters of support from phage companies in the U.S. and Europe. Their product, which has four issued patents to date, could assist in the research efforts of these companies, and could also be sold as a companion diagnostic product.

The low-cost wireless sensor technology is a platform that can be tailored to other biosensing applications.

Crowley, who used CMC’s tools in both his Masters and PhD research, says CMC Microsystems has been enormously helpful in getting the company to this point. “Access to Cadence and Synopsys design tools, and to GlobalFoundries for making these chips, was crucial,” he says.

“The central piece of this technology is custom-designed microchips. The industry-standard tools needed for this work are very expensive and not easy to get. CMC has provided access to fabrication and design tools at a reasonable cost. Without this we would be nowhere.”

Photo: Rodney Daw/Photo Features

December 2018