Low-temperature Co-Fired Ceramic (LTCC) Fab at ÉTS

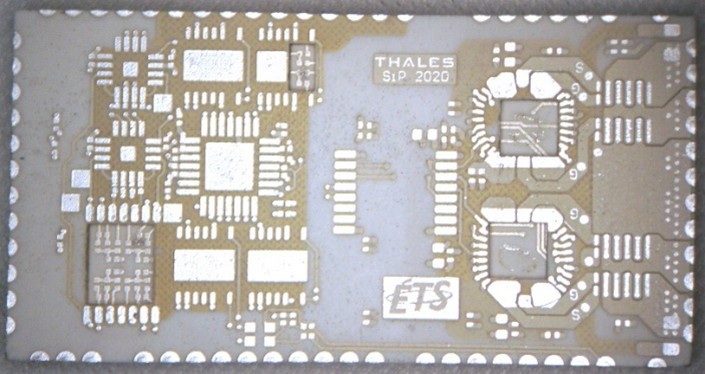

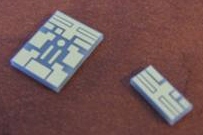

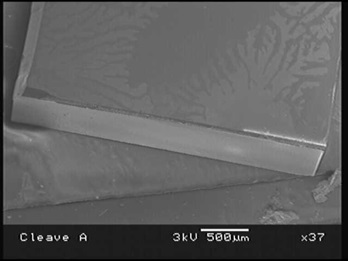

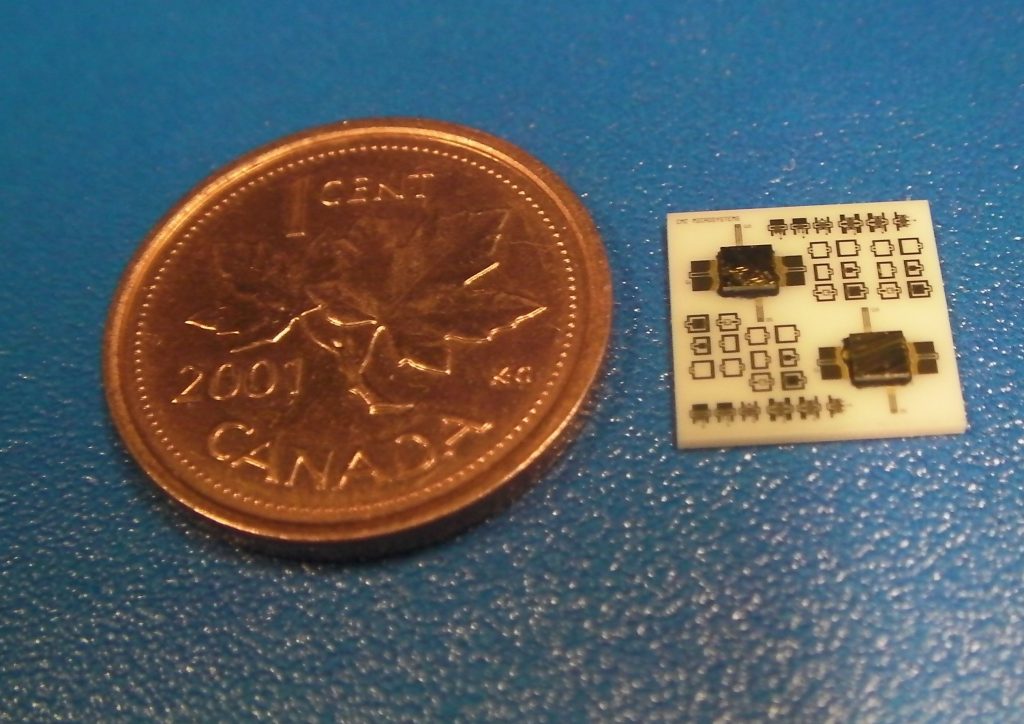

Overview LTCC technology is a general-purpose multi-layer ceramic process used in various areas, namely: Medical sensors and electronics Automotive electronics Satellite electronics and other vehicles in harsh environments RF/microwave/mm-wave communications CMC provides access to LTCC prototyping and other related services through the LTCC@ÉTS laboratory. Technical support on the LTCC process and access to the design […]

Low-temperature Co-Fired Ceramic (LTCC) Fab at ÉTS Read More »